Nijhuis i-DOSE-

Real-Time Adaptive Chemical Treatment for Wastewater

Intelligent Wastewater Chemical Dosing – Nijhuis i-DOSE

Reduce water treatment chemicals

To effectively remove solids, COD, NO3-N, and PO4-P from wastewater, chemical dosing units, pumps, and systems are often applied and needed to comply with the effluent discharge requirements. However, a fixed chemical dosing for wastewater treatment is generally not sophisticated enough to handle the actual day-to-day fluctuations in the wastewater, which can cause additional chemical and energy costs.

For example, for primary wastewater treatment, the COD load in the balance tank increases during production hours and decreases during cleaning. By using an intelligent wastewater chemical dosing system, costs for water treatment chemicals for coagulation, flocculation, and neutralization can be substantially reduced. The wastewater process can deal more easily with fluctuations in pollution load.

About i-DOSE

Nijhuis Industries has designed the “i-DOSE” system to comply with this real-time control process for the chemical treatment of wastewater, significantly reducing wastewater operational costs (e.g. chemicals, aeration, energy). Due to the intelligent dosing philosophy, the system also allows facilities to be operated at maximum performance with reduced operator presence. As well as our existing and proven i-DOSE pre-treatment applications, i-DOSE can be applied within secondary and tertiary water and wastewater treatments.

Principle of i-DOSE

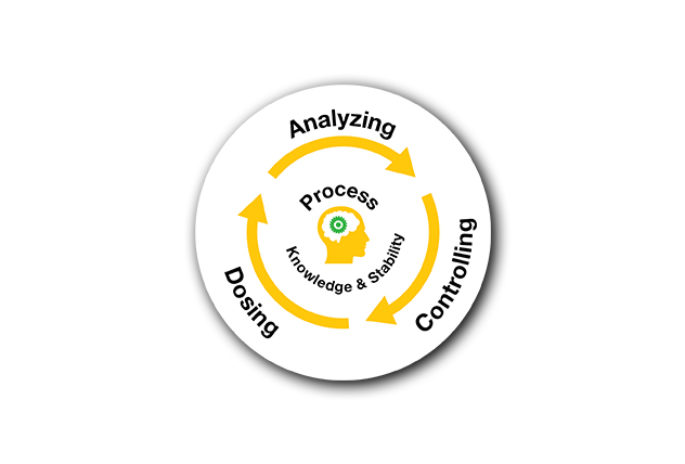

The i-DOSE philosophy is based on analyzing, controlling, and dosing the correct amount of utilities (e.g., chemicals) based on the real-time pollution in the wastewater. The Nijhuis i-DOSE consists of a UV-vis spectrometer, control & algorithm, monitoring system, and automatic cleaning mechanism.

Real-time dosing has many benefits, not just reducing chemicals

i-DOSE FACTS:

- Simple, safe, and plug-and-play design

- Empowered with an automatic cleaning mechanism

- Real-time control of the process

- Robust system

i-DOSE BENEFITS:

- Up to 30% savings on wastewater chemical consumption

- Up to 4 hours savings on additional operator’s presence per week

- Lowest possible maintenance cost due to the automatic cleaning process

- Provides peace of mind

i-DOSE IMPACT:

- Always compliant with effluent requirements

- Allows insight into trends of operation

- More process knowledge and operational stability

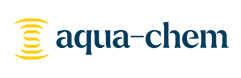

Pre-treatment – Savings on chemical consumption

Rapid COD measurement for coagulant dosing control

Typical benefits

- Avoid overdosing on chemicals.

- Reduce chemical consumption costs by up to 30%

- Better performance of flotation system.

- Always compliant, stable effluent.

- Robust measurement system.

- Reduced balance tank footprint.

- Reduced chemical sludge production.

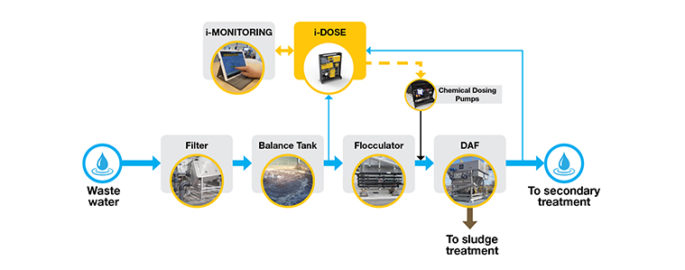

Secondary treatment – Savings on aeration and energy

Rapid BOD/TSS, NO3-N measurement for denitrification control

Typical benefits

- Controlled (de)nitrification, savings on aeration and energy.

- Always compliant, stable effluent.

- Stable nutrient balance, savings on additional nutrients.

- Peace of mind.

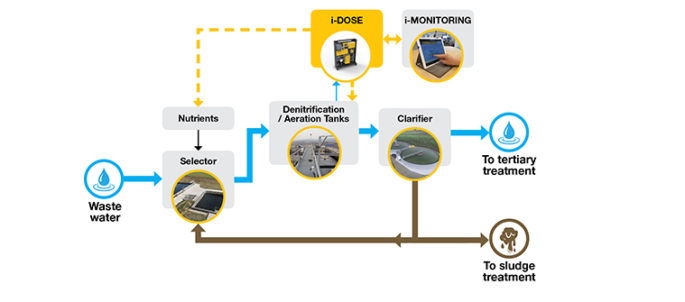

Tertiary treatment – Always compliant with effluent requirements

Rapid COD, TSS, or PO4 measurement control

Typical benefits

- Always compliant, stable effluent.

- Well-monitored, optimal treatment performance.

- Always dosing the right amount of chemicals.