Vapor Compression Distillation

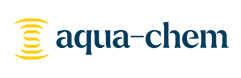

Aqua-Chem’s horizontal Spray Film design Vapor Compression Distillation systems can utilize electric heat, steam heat or function as a hybrid as a power source. This flexibility provides beverage manufacturers with a lot of opportunities for efficiently creating purified ingredient water. Our horizontal spray film design is designed to recycle latent heat energy, which makes our distillers more energy efficient. Our vapor compression distillers require minimal pretreatment (in comparison with Reverse Osmosis and other technologies) and delivers effective pyrogen removal, bacteria removal, and organics removal.

Aqua-Chem manufactures a variety of standard models of Vapor Compression Distillers and is capable of designing a system that will meet your requirements. The innovative design delivers reduced energy consumption and has less stringent feedwater requirements when compared to other distillation processes like multiple-effect systems, making Aqua-Chem Vapor Compression Distillers a popular and sustainable choice for water purification. All components are accessible from floor-level, with the compressor and pump convenient located at the edge of the skid for easy serviceability. Aqua-Chem utilizes low-speed compressor technology, which results in cooler bearing temperatures and less downtime.

FLOW RATE RANGES: 250 gpm up to 150 gph

SYSTEMS: 4 Standard Units, but custom units are available.

FEATURES

- The evaporator features a horizontal design using the Spray Film® process, which utilizes a straight tube configuration

- 316L Stainless Steel / 15-25 RA finish on contact surfaces.

- Sanitary Valves, Instruments, Pumps and Piping.

BENEFITS

- Aqua-Chem patented Spray-Film® vapor compression distillation units produce consistent, reliable, high-purity water regardless of feedwater quality fluctuations.

- Operation is fully automatic requiring minimal operator input.

- The Aqua-Chem patented Spray-Film® evaporator design provides improved wetting of the tube bundle and reduced scaling. This means less downtime for cleaning and reduced blowdown for less water waste.

Common Applications

Bottled Water

Juices

Sodas

Carbonated Beverages

Flavored Water

Ice

DOWNLOADS

Vapor Compression Distillation

Beverage Standard Units

| Model | Distillate Output (GPH) | Width (in) | Length (in) | Height (in) |

| B-200 | 200 | 60 | 65 | 102 |

| B-500 | 500 | 72 | 72 | 138 |

| BR-750 | 750 | 87 | 151 | 109 |

| BR-1000 | 1000 | 87 | 188 | 88.5 |

| BR-1500 | 1500 | 93 | 150 | 94 |

| BR-3000 | 3000 | 138 | 225 | 129 |

| BR-6000 | 6000 | 147 | 298 | 156 |

| BR-9000 | 9000 | 158 | 340 | 161 |

RESOURCES

Related Products

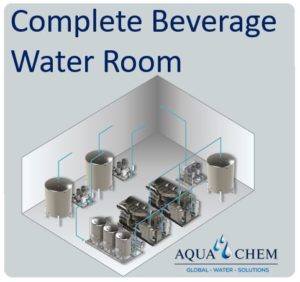

Complete Water Room

Reverse Osmosis

Carbon Towers