Pure Steam Generators

We’ve focused on all the essentials in our Pure Steam Generator design. The equipment provides consistent high quality pure steam for the Pharmaceutical, Biotechnology, Hospital, Laboratory and other industries.

All internal and external aesthetics have been designed to meet the stringent demands of sterile environments. Equipment reliability, product quality, and safety are standard features built-in to each unit.

The unique Aqua-Chem evaporator with double tube sheet design prevents product contamination to the pure steam.

Our standard validation package assists you in meeting your IQ, OQ, and PQ protocols.

CAPACITY: 675 lb/hr up to 10,150 lb/hr

SYSTEMS: 9 Standard Units, but custom units available

FEATURES

- Thermo-syphon separator section creates max centrifugal force for elimination of remaining water droplets

- Double tubesheet evaporator and heat exchanger(s) for long term reliability

- New evaporator gasket design improves seal integrity and life

- Fully automated control, with central control system integration capability

Pure Steam Generation

Standard Units

| Model | Nominal Capacity | |

| PSG-400 | 675 lbs/hr | 306 kg/hr |

| PSG-1000 | 1400 lbs/hr | 675 kg/hr |

| PSG-1200 | 1500 lbs/hr | 680 kg/hr |

| PSG-1600 | 2900 lbs/hr | 1315 kg/hr |

| PSG-2000 | 3200 lbs/hr | 1415 kg/hr |

| PSG-2600 | 4450 lbs/hr | 2018 kg/hr |

| PSG-3900 | 5000 lbs/hr | 2267 kg/hr |

| PSG-4750 | 7500 lbs/hr | 3402 kg/hr |

| PSG-6100 | 10150 lbs/hr | 4604 kg/hr |

DOWNLOADS

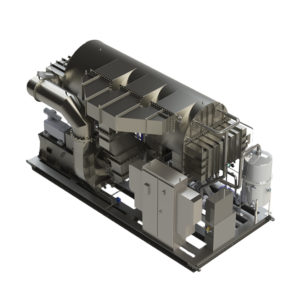

Interactive Process Flow Diagrams (PFDs)

Click on the components of the PFD to learn more.

Pure Steam Generator Skid (PSG)

DESIGN FEATURES

• Shell-side evaporation design ensures heat transfer

surface will resist the formation of scale

• Submerged-tube, rising-film design eliminates dry

tube “hot spots”

• Fully automated control, with central control system

integration capability

Sanitary Booster Pump

Sanitary, Energy-Efficient, multi-stage booster pumps mounted on a heavy-duty frame with a variable Frequency Drive (VFD) to vary the motor input based on demand.

Pure Steam

Clean and Pure Steam from Aqua-Chem PSG systems generate high-quality steam that is devoid of condensate, debris, and other impurities for humidification, solvent, and sterilization (SIP) applications.

Blowdown Cooler

Aqua-Chem’s thermally efficient process uses a heat exchanger to recover waste heat from any blowdown, simultaneously pre-heating the feed water supply and reducing the temperature of water discharged to facility drains.

Quality Divert Valve

An optional quality monitoring system verifies that feed water conditions meet exacting specifications and diverts steam that cannot be qualified. Heat exchangers are used to condense and cool rejected product so that it can be safely discharged to drain.

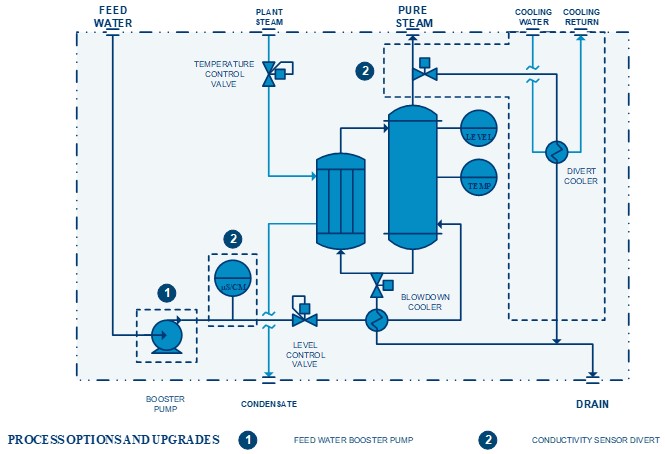

Pharmaceutical Water Room with Pure Steam Generator PFD

Water Conditioning System

Pretreats municipal potable water for to remove fine sediment and mineral hardness for use in membrane or distillation treatment processes using media or direct filtration and water softener resins.

PW/ WFI Generation System

Removes minerals, bacteria, and other organics according to pharmaceutical water specifications using membrane filtration and ion exchange resins or distillation.

Product Water Storage Tank

Storage & Distribution

Aqua-Chem supplies high-quality storage and distribution tanks in a variety of sizes and materials to meet our customers needs. We provide strategic solutions for projects of all sizes and levels of complexity.

Distribution Loop System

We’ve focused on all the essentials in our Pure Steam Generator design. The equipment provides consistent high-quality pure steam for the Pharmaceutical, Biotechnology, Hospital, Laboratory and other industries.

Designed to monitor and control flow, pressure, temperature, and quality of compendial waters through a facility distribution loop and with integral periodic or continuous chemical, ozone, or high temperature sanitization options.

RESOURCES

Related Products