BEVERAGE REVERSE OSMOSIS

Aqua-Chem’s range of Reverse Osmosis (RO) Systems are the result of decades of experience engineering complete water rooms to create the most efficient and sustainable systems to produce purified ingredient water for the beverage industry. Aqua-Chem Reverse Osmosis Systems are highly customizable utilizing a wide range of membranes from a variety of suppliers.

This flexibility means that Aqua-Chem can balance all aspects of the purification process at your facility; feed water conditions, permeate quality requirements, energy consumption, and recovery goals to create the most efficient and sustainable system for your facility.

FLOW RATE: 100 to 400 gallons per minute (gpm)

CAPACITY: Single-pass and Double-pass Configurations

FLEXIBLE: Additional Flow Rates and Customizations are Available.

FEATURES

- Pretreatment and Polishing processes integrated into one system

- VFDs on pump motor(s) to increase efficiency

- Vertical multistage pumps are longer-lasting and provide a higher level of reliability

- Convenient sample ports on each housing for easy quality monitoring

- Comprehensive Factory Acceptance Testing (FAT) performed in our ISO9001 certified facility

- Fully programmable alarm conditions customized to your system requirements (fixed or adjustable)

- Hot water sanitizable units are available

- Allen Bradley PLC and Touchscreen HMI for easy monitoring and seamless integration with existing equipment

- Aqua-Chem’s field service team supports you during and after commissioning

- We offer operator training, preventative maintenance programs, and more

- Clean in Place (CIP)- Full machine or bank-by-bank capability

OPTIONS

- Integrated Concentrate Recovery to increase efficiency

- Stainless Steel Membrane Pressure Vessels

DOWNLOADS

Reverse Osmosis

Standard Beverage Systems

| MODEL | Design Capacity | Nominal Product Flow Range (gpm) | L x W x H (in) | Est. Dry Shipping Weight (lb) | Est. Wet Op. Weight (lb) | |

| Beverage RO-100 | Single Pass | 60-110 | 268 x 53 x 72 | 3860 | 6800 | |

| Beverage RO-200 | Single Pass | 150-205 | 268 x 53 x 74 | 5000 | 12400 | |

| Beverage RO-300 | Single Pass | 220-315 | 268 x 84 x 72 | 7900 | 15000 | |

| Beverage RO-400 | Single Pass | 315-415 | 268 x 90 x 87 | 8350 | 18000 | |

| Beverage RO-75 | Double Pass | 75-100 | 288 x 75 x 72 | 4350 | 9200 | |

| Beverage RO-150 | Double Pass | 150-185 | 268 x 80 x 74 | 5120 | 12400 | |

| Beverage RO-250 | Double Pass | 220-285 | 288 x 96 x 74 | 9000 | 21000 | |

| Beverage RO-350 | Double Pass | 315-375 | 288 x 108 x 87 | 9815 | 25000 | |

Treatment ability of the RO system is dependent on feed water quality.

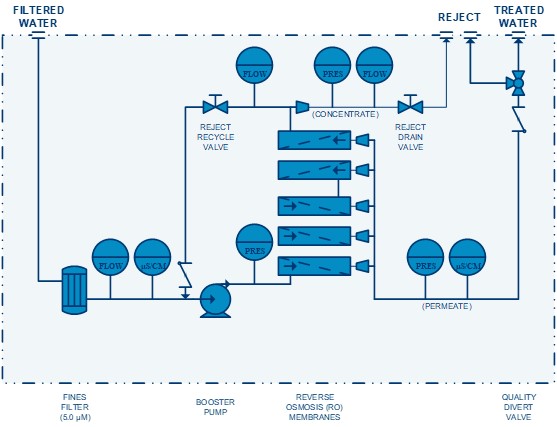

Interactive Process Flow Diagram

Click on the components of the PFD to learn more.

Reverse Osmosis System Skid

Cartridge Filter

A cartridge filter removes particles and some chemicals from feedwater. By removing these particulates from the feedwater the cartridge filter is protecting the reverse osmosis (RO) membranes.

High Efficiency Booster Pump w/ VFD

Energy-Efficient, multi-stage booster pumps mounted on a heavy-duty frame with a variable Frequency Drive (VFD) to vary the motor input based on demand.

Reverse Osmosis (RO) Membranes

Aqua-Chem’s range of Reverse Osmosis (RO) Systems are the result of decades of experience engineering complete water rooms to create the most efficient and sustainable systems to produce purified ingredient water for the beverage industry. Aqua-Chem Reverse Osmosis Systems are highly customizable utilizing a wide range of membranes from a variety of suppliers.

RO Permeate

Reverse Osmosis permeate is the product or 'clean' water that a system of RO membranes creates from feedwater.

RO Concentrate

Reverse Osmosis (RO) Concentrate is the 'dirty' water and impurities that are rejected by the reverse osmosis system.

Quality Divert Valve

The quality divert valve allows control during the cleaning process and allows for the flow to be diverted away from the permeate storage tank and then switched back again after the cleaning process has completed.

Related Products