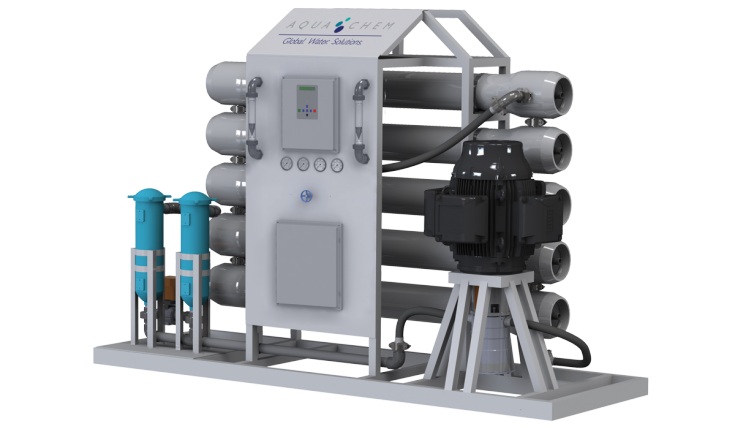

ACX3 SERIES

Industrial Seawater Reverse Osmosis Systems

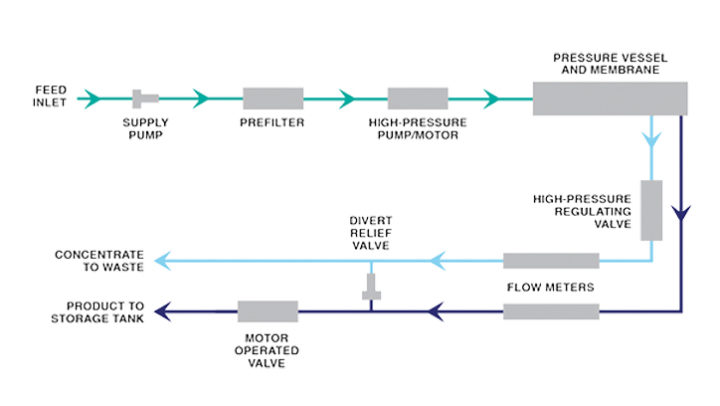

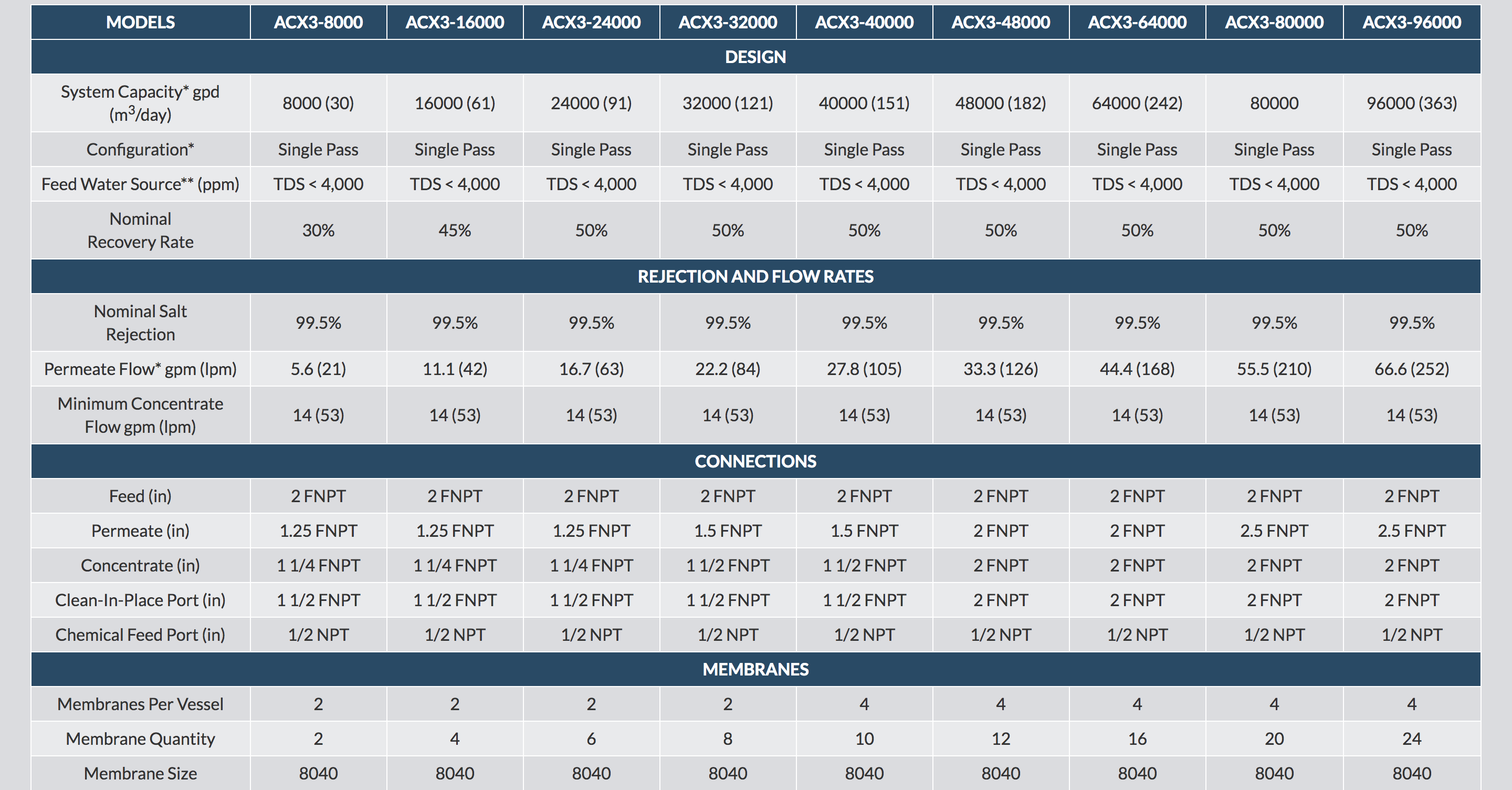

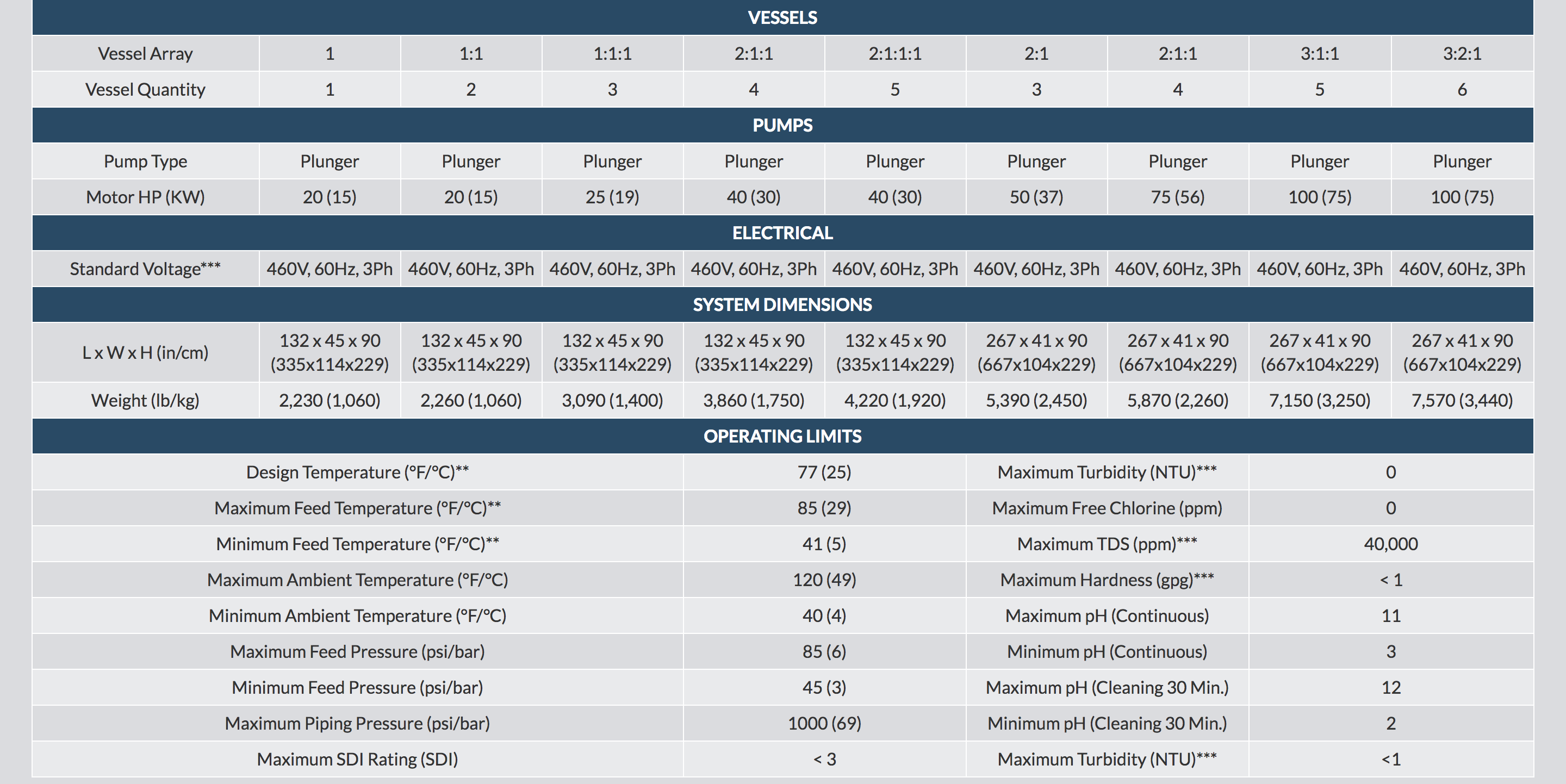

ACX3-Series Industrial Seawater Reverse Osmosis Systems are engineered for seawater desalination and other high total dissolved solids (TDS) applications requiring high pressure pumps. The ACX3-Series systems are rated to handle total dissolved solids as high as 38,000 ppm (with higher levels of TDS achievable by adjusting the recovery and /or flux rate).

Downloads

![]()