TORRENT™ WFI Packaged Membrane System

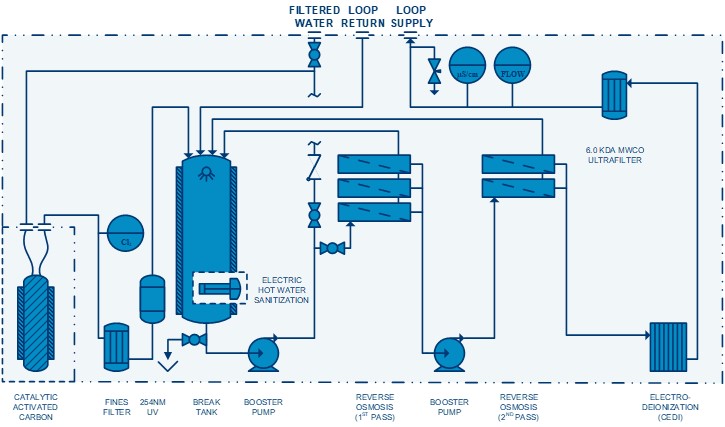

The TORRENT™ WFI Packaged Membrane WFI System generates compendial water that exceeds current USP, PhEur, and JP requirements for parenteral solutions and other critical applications. A triple-membrane barrier is used to deliver purified water at ambient temperatures and ensures maximum quality with minimal risk. The innovative form factor improves ease of use, includes fully-automated operation and hot water sanitization, and is fully factory tested for fast installation, start-up, and qualification. All TORRENT™ water systems are engineered for performance and reliability using only non-proprietary, premium components including Mettler-Toledo instrumentation, Bürkert valves, and IonPure® CDI-LX™ modules.

Catalytic Carbon Exchange Filtration

Catalytic carbon exchange filters deliver the effectiveness of activated carbon for removing chlorine and chloramines from feedwater without the costly downtime to service it. Our system is equipped with a spare carbon filter, so that when it's time to clean or replace your carbon you can simply swap out the tanks and keep production running. The offline tank can be cleaned and prepped to be used as a replacement for the next carbon change out.

Cartridge Filter

A cartridge filter removes particles and some chemicals from feedwater. By removing these particulates from the feedwater the cartridge filter is protecting the reverse osmosis (RO) membranes.

254nm Ultraviolet (UV) Disinfection

Ultraviolet (UV) Disinfection inactivates pathogenic microorganism, such as viruses, bacteria, and parasites. Ultraviolet disinfection is environmentally friendly and produces no chemical by-products. UV transfers electromagnetic energy from a mercury arc lamp to an organism's genetic material (DNA and RNA). Ultraviolet lights are commonly referred to as 'germicidal' lamps thanks to their decades of use as a disinfectant for air, water, and nonporous surfaces.

Process Break Tank

A 316L SST break tank provides a hydraulic ‘break’ in the system for a stable and easy to operate ‘open loop’ design with added Clean-In-Place functionality. All feedwaters are disinfected, and tank walls are continuously washed down to reduce micro-contamination risk.

Hot Water Sanitization (HWS)

Built-In Hot Water Sanitization allows for effective and easy sanitization of the system and break tank.

Reverse Osmosis (RO) System

Aqua-Chem’s range of Reverse Osmosis (RO) Systems are the result of decades of experience engineering complete water rooms to create the most efficient and sustainable systems to produce purified water and water for injection for pharmaceutical applications.

Reverse Osmosis (RO) System (2nd Pass)

Aqua-Chem’s range of Reverse Osmosis (RO) Systems are the result of decades of experience engineering complete water rooms to create the most efficient and sustainable systems to produce purified water and water for injection for pharmaceutical applications.

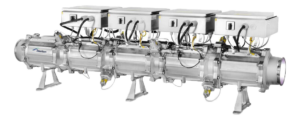

Continuous Electrodeionization Modules (CEDI)

The Continuous Electrodeionization Modules (CEDI) creates an electric field and resin to captures ions and deionize water and passes the separated dissolved ions (impurities) to the concentrating compartments.

6,000 Dalton MWCO Ultrafilter (UF)

6,000 Dalton MWCO Ultrafilter (UF) meets global WFI standards to comply with USP, JP and PhEur requirements for parenteral solutions and other critical applications.

High-Efficiency Booster Pump

Energy-Efficient, multi-stage booster pumps mounted on a heavy-duty frame with a variable Frequency Drive (VFD) to vary the motor input based on demand.

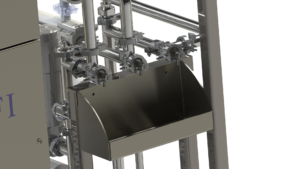

Product Water Sampling

An ergonomic sample station positions key monitoring points at the front of the system for easy, error free, QA/QC micro testing of grab samples without any mess thanks to an integral drain system.

Water for Injection (WFI)

Aqua-Chem Water for Injection systems produce high-purity validated water that exceeds the compendial requirements set by the USP, PhEur, and JP for parenteral applications like vaccine manufacturing and gene therapy. Microbial and endotoxin control are paramount and robust equipment designs ensure maximum product safety and quality.