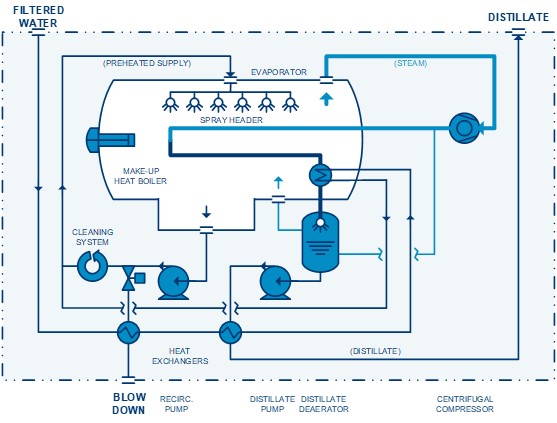

Vapor Compression Distillation System

Preheated Supply

Incoming feedwater is preheated by the outgoing blowdown and distillate.

Spray Header

Feedwater and recirculation water are combined and sprayed over the outside of the evaporator tubes. Our patented Spray-Film® evaporator design

provides improved wetting of the evaporator tubes and reduced scaling. This means less downtime for cleaning and higher operating efficiency.

Make-up Heat Boiler

The evaporator features a horizontal design using the Spray Film® process. It has a straight tube or U-tube configuration depending on size. Our process has eliminated the bottom hydraulic gasket, thus reducing maintenance.

Clean-In-Place (CIP) System

The Spray Film® design includes a built-in, online cleaning system for removing scale and for repassivation. The cleaning system helps reduce maintenance costs and maintain high operating efficiency.

Feedwater Heat Exchangers

Aqua-Chem VC distillers are thermally efficient thanks to heat exchangers that recycle latent heat from the distillation process. Waste heat from blowdown and from the distillate is extracted and for use in pre-heating the evaporator’s water supply.

Distillate Pump

The stills can be designed to produce hot (85° C) distillate, cold (32° C) distillate or both. Output can range from 300 to 7,200 GPH.

Recirculation Pump

Aqua-Chem’s Horizontal Spray Film® utilizes recirculation pumps to create water droplets for efficient heat transfer and conversion to pure steam. The recirculation loop is also used to drive the distiller’s cleaning system and blowdown process.

Distillate Deaerator

A 316L Stainless Steel (SST) deaerator removes carbon dioxide, oxygen and other noncondensable gases from the feedwater or distillate.

Centrifugal Compressor

Steam generated inside the evaporator is drawn through the demisters by the centrifugal compressor, and the temperature is increased in the compression process. Low-speed, direct drive compressors are offered on all units 1,600 GPH and above. High-speed compressors on smaller units use high-speed journal bearings for maximum life.

Distillate

Our stills can be programmed for variable distillate capacity with turn-down to 50% of design flow using a variable frequency drive (VFD) on the compressor motor. Variable capacity allows the still to match the draw-down on the WFI tank(s) while reducing the number of starts and stops.

Blowdown

Blowdown is the concentrated discharge the is a byproduct of the distillation process. The outgoing blowdown is used to preheat the incoming feedwater, contributing to the energy efficiency.