Spiral wound membrane elements are the heart of your Reverse Osmosis (RO) filtration system. RO membranes feature a semi-permeable surface that allows water to pass through while selectively rejecting most contaminants from the feed water source. The elements can filter virtually all suspended and dissolved contaminants and quickly plug when used for “direct filtration.” Hence, a “cross-flow” configuration is typical where a portion of water is sent to drain to limit fouling or scale buildup. Residential household, wastewater, and seawater RO systems will typically purify 25-50% of their feed water supply. Commercial and industrial RO systems average 75% recovery but operate anywhere between 65-95% depending on feedwater quality, selected pretreatment equipment, and the number of membranes used. The waste water stream often referred to as “brine” or “reject,” consists of concentrated salts and organics and is usually discharged directly to the sewer. RO membrane performance is sensitive to temperature and feedwater quality changes and fouling or chemical attacks will gradually impact the quality and quantity of water produced. So, what do you need to know to ensure your RO system is running effectively and efficiently? First, let’s explore some of the common questions you might have about Reverse Osmosis Membranes.

TOP 5 QUESTIONS ABOUT CHANGING RO MEMBRANES: ANSWERED BY EXPERTS

How often should I change the Reverse Osmosis Membranes?

Well, it depends… Sorry, but the recovery percentage, feedwater quality, pretreatment effectiveness, maintenance regularity, applications requirement, and a whole host of other factors play into determining the cleaning or replacement interval for RO membranes. You need to be very in tune with your system and understand how it performs overall and how seasonal fluctuations in feedwater like temperature and quality can impact performance. In general, systems with higher recovery or systems that treat dirtier water see the most frequent cleanings or replacements. Certain industries follow rough guidelines with most pharmaceutical applications cleaning membranes at least every year and replacing on a set interval every 3-5 years, beverage manufacturers cleaning quarterly and running to fail within 3-7 years, and municipal and seawater replacing annually. These numbers can vary, but they guide when you need to analyze your system performance to see if replacement makes sense.

Why should I change my Reverse Osmosis Membranes?

There are a variety of environments and variables that can affect the rate that your membranes degrade. Membranes that need to be cleaned or replaced will let you know in the form of performance data when you see that your energy consumption has increased or if you notice higher pressures are required to make the same amount of water. Some changes, like decreased salt rejection, are symptoms of permanent damage like chemical attack and

cannot be recovered with cleaning. While RO systems can be lower energy consumers than other purification methods like distillation, you can still see increased costs by running membranes that aren’t performing as they should. Keep in mind that if you decide not to change your membranes for an extended amount of time, you risk the service life of every other component and downstream equipment in your system.

What about cleaning RO membranes?

Cleaning your membranes is a great way to extend their service life. Membranes that are cleaned and well maintained will save you money in reduced energy costs, less waste, and better product quality. If you don’t have a membrane cleaning program in place, contact your service provider to get a longer service life out of your membranes. Different cleaning procedures are used to remove different types of contamination, and elements can be cleaned in place (CIP) with the right equipment or removed and cleaned off-site. For example, acids are often used to dissolve hardness scaling, bases (caustic) are often used to remove organic fouling, surfactants and chelating agents are used to remove fouling or heavy metals. In addition, there are many suppliers of proprietary cleaning solutions that address multiple contaminants simultaneously. Keep in mind that it’s not always possible to gain back all the baseline performance of the element, and aggressive cleaning can damage the membrane surface. Therefore, the best strategy for scale and fouling is to prevent it from forming in the first place.

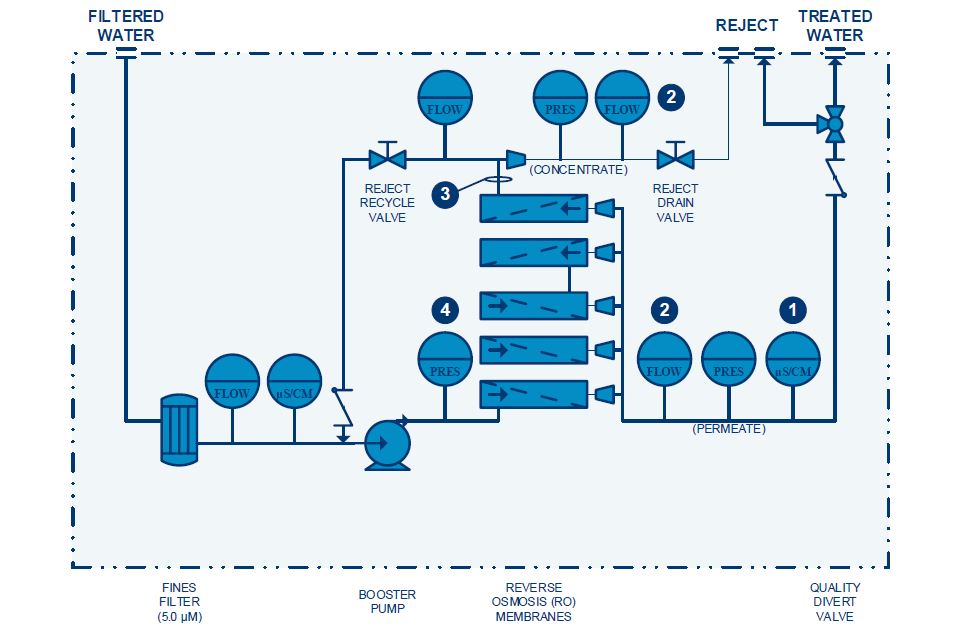

1) RO Permeate Quality: Typically 1-3% of the feedwater TDS or Conductivity but is normally affected by temperature and presence of dissolved gasses. An increase in salt passage (inversely, decrease in salt rejection) may indicate membrane or o-ring damage.

2) RO Permeate Recovery Rate: Typically 75% for commercial/industrial ROs and is dictated by the pressure vessel array, membrane type, and feedwater quality. Recovery is set by adjusting the pump driving pressure and balancing the reject valves. Adjustments are normally required due to temperature changes but can be affected by fouling or scale formation on the membranes. Too much recovery accelerates membrane fouling and scale formation.

3) RO Reject Flow Rate: Typically 25 GPM per final stage 8” Pressure Vessel. Too little flow accelerates membrane fouling. System recovery can be increased by diverting a portion of this flow back to the front of the unit with a tradeoff

in product quality and increased scale formation risk (due to salt concentration cycling within the RO).

4) RO Normalized Driving Pressure: Used to determine when to clean or replace RO membrane elements. Normalization calculations are used to offset the effects of temperature and osmotic back pressure when evaluating RO performance data. Baseline readings are taken with new or freshly cleaned elements and a 10-15% increase in driving pressure from fouling, biofilm, or scale formation is often used to trigger a cleaning procedure.

Aqua-Chem is your complete supplier for any water purification challenge. Aqua-Chem is ready to help you get the most out of your equipment, from replacement parts like membranes to service and maintenance. Click here to find the solution that fits your unique application.

What Brand of Membranes Should I Use?

There are a variety of environments and variables that can affect the rate that your membranes degrade. Membranes that need to be cleaned or replaced will let you know in the form of performance data when you see that your energy consumption has increased or if you notice higher pressures are required to make the same amount of water. Some changes, like decreased salt rejection, are symptoms of permanent damage like chemical attack and cannot be recovered with cleaning. While RO systems can be lower energy consumers than other purification methods like distillation, you can still see increased costs by running membranes that aren’t performing as they should. Keep in mind that if you decide not to change your membranes for an extended amount of time, you risk the service life of every other component and downstream equipment in your system.

Can I Change my Membranes, or Should my Service Partner?

Changing RO membrane elements is a simple task that is labor-intensive, includes repetitive steps that can be overlooked, and sometimes requires unusual handling when using specialized membranes. Therefore, Aqua-Chem recommends a professional field service technician performs or leads the task to ensure no mistakes are made, especially if membrane replacement is an infrequent activity for the system owner. Aqua-Chem field technicians are trained on all makes and models of reverse osmosis equipment and have many years of experience to ensure proper installation and peak performance.