Recover & Reuse Clean in Place (CIP) Liquid-

AECO-CIP: Plug & Play Systems

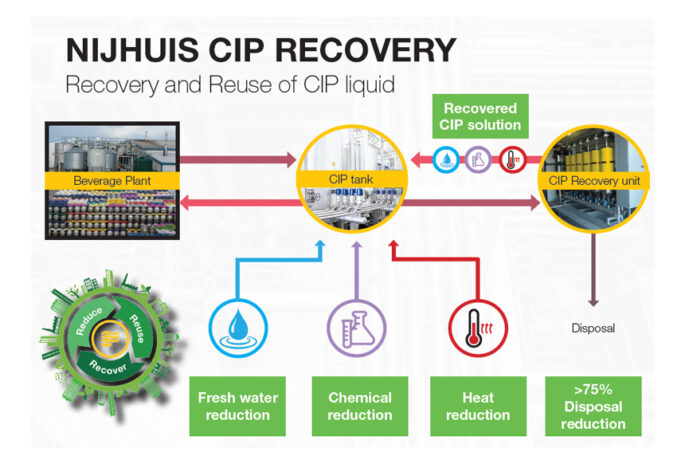

Recovery and Reuse of CIP liquid

In-process recovery solutions are crucial to achieving the increasingly demanding environmental requirements to create a more sustainable way of operating beverage plants.

The Nijhuis AECO-CIP recovery unit is a plug & play packaged recovery system to treat spent CIP solutions (i.e., hot soda based). While the CIP agents and heat remain in the recovered stream, the organic fouling, solids, and part of the inorganic soluble content will be captured by special membranes and concentrated prior to disposal. The system can be applied for both caustic, acid, and enzymatic CIP solutions. Typical hydraulic recovery of 75 to 90% can be achieved.

We offer modular expanded packaged plants with capacities between 100 to over 2600 gph. In order to determine the best economical and sustainable solution, we also offer our i-CONSULT laboratory services to investigate your specific situation.

APPLICATIONS

- (Craft) Breweries

- (Sparkling) Wine & Spirits

- Milk & Liquid Milk Products

- Fruit Juice

- Liquid Food, Soft Drinks & Water

- Coffee

CUSTOMER BENEFITS

- Recover CIP solutions by membrane cleaning

- Low energy consumption by NDNF membranes

- Reduce waste disposal costs

- Retain CIP energy by smart integration of heat exchangers

- Reduced fresh makeup water, chemicals, and heat

- Increased CIP availability by shortened preparation times