What is Vapor Compression Distillation?

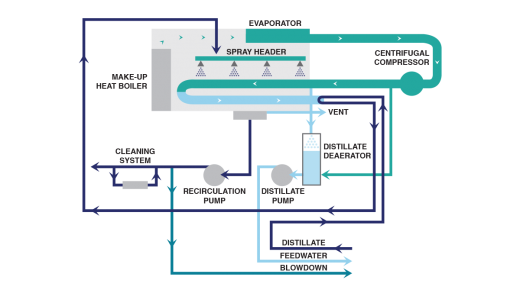

In terms of distillation, Vapor Compression, or VC, refers to Mechanical Vapor Compression (MVC) technology, which is utilized to impart energy (in the form of heat) to evaporated water (i.e. vapor) through centrifugal compression. Vapor Compression is much more efficient in distilling water compared to older technology, which requires massive amounts of thermal energy input (i.e. plant steam, electrical heaters) applied over a multi-pass evaporation/condensation process.

Aqua-Chem uses vapor compression (VC) for most of its distillation systems, a process that uses its own compressed steam as its primary heat source. The result is vastly improved efficiency over other distillation methods. Our vapor compression distillers use only about half the energy of multi-effect distillation, providing you high purity water at a significant cost savings.

Aqua-Chem VC distillers have set the standard for reducing maintenance costs and downtime while increasing operating life—with units that continue to provide excellent service after more than 30 years of operation. Our commitment to ongoing design improvements keeps us in the forefront as we strive to remain the most innovative designer of VC stills.

All Aqua-Chem vapor compression distillers incorporate our patented Spray-Film evaporator design which provides improved wetting of the tube bundle and reduces scaling compared to rising-film designs. Two significant benefits are less downtime for cleaning and reduced blowdown (resulting in less wasted water). This design also includes built-in on-line cleaning for easier removal of scale. Aqua-Chem distillers provide improved safety and ease of maintenance with all major components accessible from floor level. The compressor and pumps are easily accessible at the edge of the skid.

Our product development group is currently working on options for direct drive low-speed compressors for most of our vapor compression equipment. These models will continue to offer greatly increased reliability and longer life compared to existing designs and competing products. By working closely with our compressor manufacturer to develop optimized proprietary designs, the operating performance of our compressors are in the forefront and unrivalled in the industry. Our experience with several installations around the world indicates that these type of compressors will run for 15 years or more without major overhaul or replacement when properly maintained.

Regardless of whether your facility requires a 300 U.S. gallons per hour vapor compression model or a larger unit, Aqua-Chem’s proven technology assures high purity water required for any application, handling High Suspended Solids and High TDS feedwater sources, and providing the highest purity water required for any operation.

Vapor Compression Videos